GENERATE SUPPLIERS ORDERS

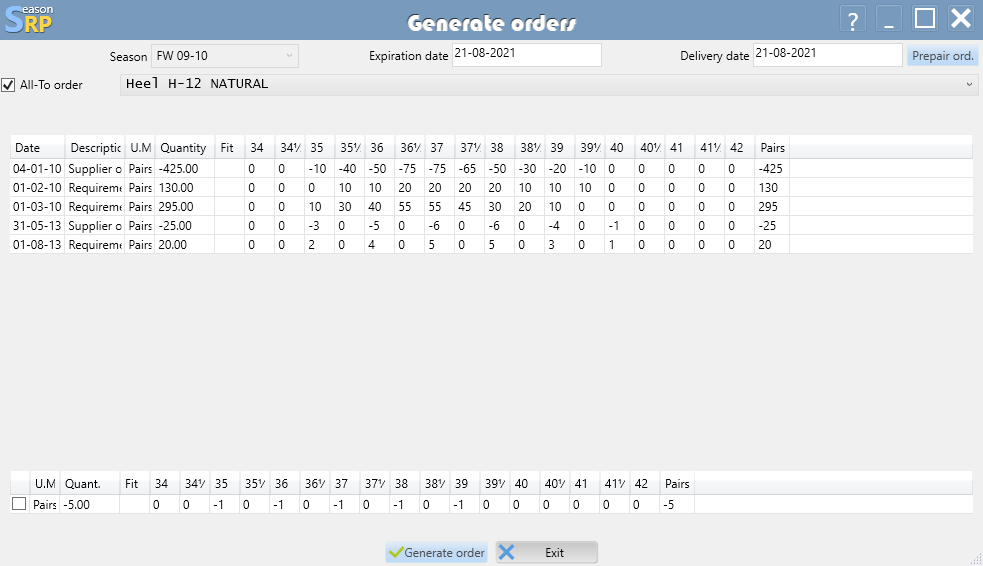

To place order to suppliers is very easy and simple, all you have to do is run the “generate supplier orders” procedure, and select de desired parameters:

- Season: this is the season to process.

- Order expiry: this date will select and calculate all material needed for the orders with this deadline, it is very useful because usually the manufacturer don’t want to buy all the materials for all the orders bur for instance only the materials for the orders within 3 months and place another order for the remaining ones.

Consign material : this is the delivery date that will be printed on the suppliers orders. Pressing the button “Update” the process start and the following combobox will be filled with all the materials needed. Selecting one by one all the items in the combo box, the grid will display the dates and quantities needed with a total at the bottom, by clicking confirmed (red if it has to be ordered green if already ordered) the components will be ready to be ordered. Pressing “confirm orders” all the components that we previously selected will generate automatic orders to their suppliers (see basic archive insertion point 4).